Stage 2 – Process Qualification: For the duration of this phase, the process design and style is verified as being able to reproducible professional production.

The underlying basic principle is you cannot be positive of quality by only testing the concluded products. Rather, you must Construct in good quality – and also efficiency and safety – through each move with the production process. This really is what the A few Phases of Process Validation aims to obtain.

This technique is critical to take care of the validated status of your plant, gear, producing processes and Pc programs. Doable good reasons for starting up the revalidation process involve:

Stage 1 – Process Design and style: The business process is defined throughout this phase based on expertise received by growth and scale-up routines.

Improve and be capable to apply your comprehension of ICH terminology such as the concepts of a science- and threat-centered method of the process validation lifecycle.

An FDA investigative engineer shares that one of many main process validation troubles encountered during inspections of US production services would be the failure to exhibit self-confidence in the process by good documentation of qualification protocols like:

In such scenarios quantity of batches of various strength may perhaps lower with appropriate justification and important approval from Shopper / Regulatory company.

An operational qualification template is applied to accomplish the process validation protocol by recording all expected details like calibration tools, education documents, and person’s manuals and indicating the results from Manage factors, alarms, and outputs. Conveniently outline distinct issues on the products/program like ordinary ailments and worst situation conditions with using this process validation protocol – operational qualification template.

Furthermore, QA shall evaluate the variability ‘involving’ Validation Batches by comparing the process parameters and check outcomes of each batch at each phase of tests with the opposite PV Benefits.

The next phase involves demonstrating that the process is capable of persistently making products which meet the predetermined click here good quality characteristics. It involves the execution of validation protocols to validate the process general performance and the collection of information to guidance the validation.

Just in case more parameters of any phase really should established. Attache an addendum to the concern internet pages with signal and date of Generation, QA and FDD Associates.

Having said that, its inherent threats call for watchful arranging and execution to be sure compliance with regulatory and operational demands.

In the simplest terms, should you specified that a component need to be exactly 20 mm in length, you may verify that by measuring the elements that your process validation protocol process generates in opposition to the specification of twenty mm.

On satisfactory completion of pre requisite pursuits, Put together the process validation protocol as described beneath.

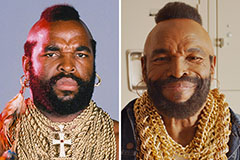

Mr. T Then & Now!

Mr. T Then & Now! Kelly Le Brock Then & Now!

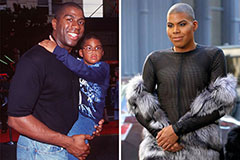

Kelly Le Brock Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!